PRODUCTS LIST

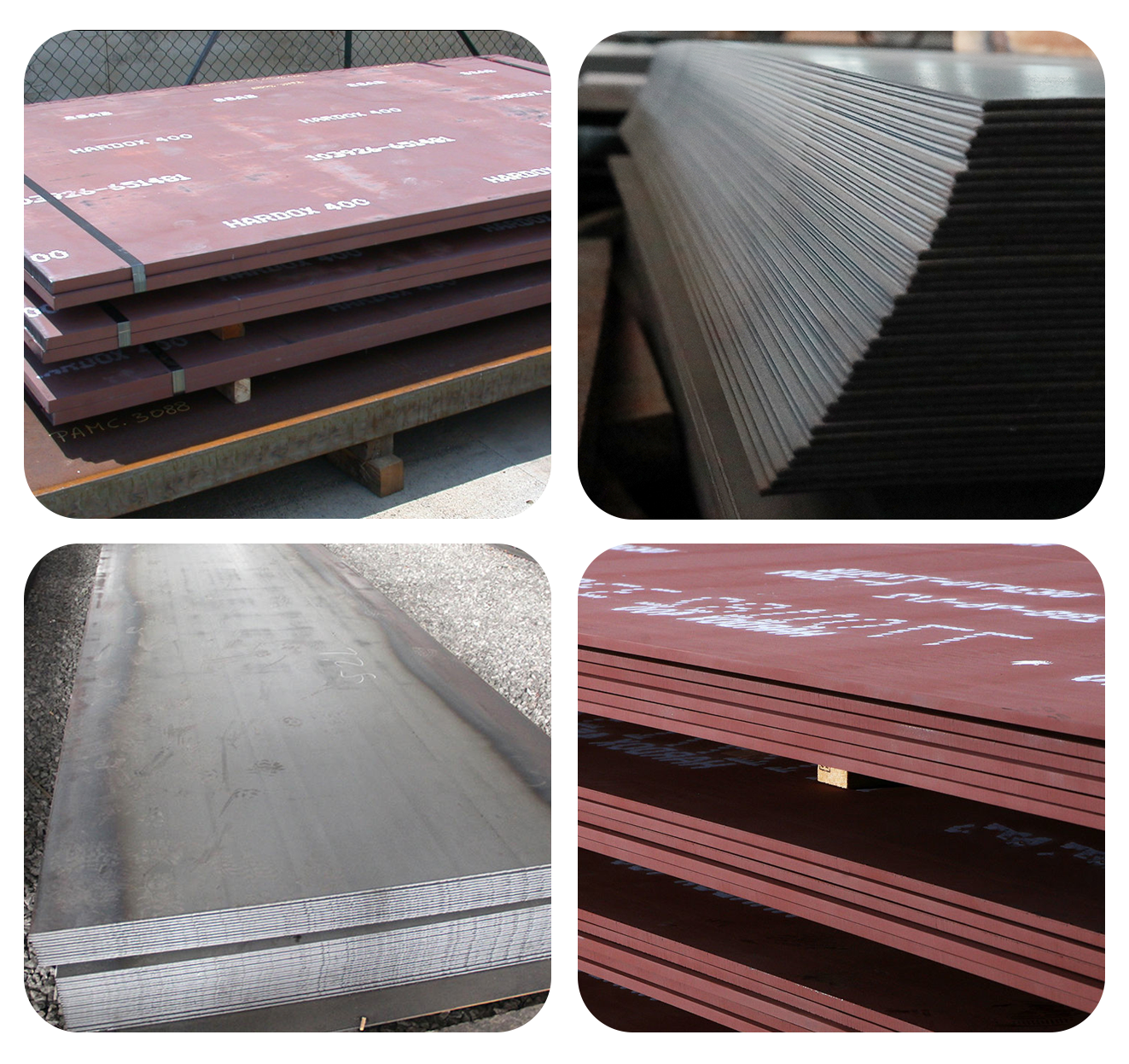

Wear-resistant Steel Plate

Category:

Carbon Steel Plate

Keywords:

Carbon Steel Plate

Product Introduction

Product Description

Chrome Carbide Overlay Wear Plate are manufactured by welding one or multiple wear resistant layers on a medium or low carbon steel base plate.

The overlay alloy has a high amount of chromium carbide hard particles which makes the plate have good wear and impact resistance.

Overlay thickness range: 3-25mm

Wear plate size: 1500*3000, 1400*3000,1400*3400, 1400*3500, 2100*3500, customized.

Chrome Carbide Overlay Wear Steel Plate are used to make many complex wear parts to be positioned in high wear places.

We can provide wear plate cutting, bending, bolting, punching and welding according to customer's drawings.

1.Wear-resisting steel plate is composed of low Carbon Steel Plate and alloy wear-resisting layer. When working, the matrix provides comprehensive properties such as strength, toughness and plasticity of resisting external forces, and the alloy wear-resistant layer provides wear-resistant properties that meet the requirements of specified working conditions.

2.Wear-resisting steel alloy wear-resisting layer and base plate are metallurgical combination. By means of special equipment and automatic welding process, the high-hardness self-protecting alloy wire is uniformly welded on the substrate, and the composite layers are one to two or even more. In the composite process, due to the different shrinkage ratio of the alloy, uniform transverse cracks appear, which is a significant feature of the wear-resistant steel plate.

3.The wear resistant layer of the alloy is mainly chromium alloy, while manganese, molybdenum, niobium, nickel and other alloys are added. The microhardness of carbide can reach above hv1700-2000, and the surface hardness can reach hrc58-62. Carbide alloy has a strong stability at high temperature, maintain a high hardness, but also has a good oxidation resistance, within 500℃ completely normal use.

4.The wear-resistant layer has narrow channel (2.5-3.5mm), wide channel (8-12mm), curve (S, W), etc. It is mainly composed of chromium alloy, while manganese, molybdenum, niobium, nickel, boron and other alloy components are added. With 40-60% carbide content, the microhardness can reach above HV1700 and the surface hardness can reach hrc58-62.

Product Specification

|

Product |

Wear Resistant Steel Plate |

|

Standard |

AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

|

Thickness |

3-120mm |

|

Width |

600-1500mm, 1800-2000mm,2500-3500mm |

|

Length |

2000-3000mm, 6000-12000mm |

|

Grade |

NM360, NM400, NM450, NM500, AR360, AR400, AR450, AR500, AR550 QUARD400, QUARD450, QUARD500, FORA400, FORA500, RAEX400, RAEX450, RAEX500 |

|

Surface treatment |

Clean, blasting and painting according to customer requirement |

|

Technique |

Cold rolled and hot rolled |

|

Capacity |

10000 tons/month |

|

Package |

Export standard packing: wooden cases or boxes to be packed;We will pack the goods according to the factory's requirements for export. Or according to customer requirements.In addition,we will give the product good surface protection. |

|

Application |

metallurgy, coal, cement, power stntion, mining, building materials, petrochemical industry |

| Minimum Order Quantity | 25Tons |

NM360 NM400 NM450 NM500 Wear Resistance Steel Plate

Chemical Component

|

Steel/Grade |

C |

Si |

Mn |

P |

S |

AL |

Cr+Ni+Mo |

Nb+V+Ti |

|

NM360/AR360 |

0.10-0.30 |

0.20-0.40 |

1.00-2.00 |

≤0.015 |

≤0.003 |

≥0.20 |

<0.6 |

Trace Amount |

|

NM400/AR400 |

0.10-0.40 |

0.20-0.40 |

1.00-2.00 |

≤0.015 |

≤0.003 |

≥0.20 |

<0.9 |

|

|

NM450/AR450 |

0.10-0.40 |

0.20-0.40 |

1.00-2.00 |

≤0.015 |

≤0.003 |

≥0.20 |

<1.2 |

|

|

NM500/AR500 |

0.10-0.40 |

0.20-0.45 |

1.00-2.00 |

≤0.015 |

≤0.003 |

≥0.20 |

<1.5 |

|

|

NM550/AR550 |

0.10-0.50 |

0.20-0.45 |

1.00-1.50 |

≤0.015 |

≤0.003 |

≥0.20 |

<2.0 |

|

|

NM600/AR600 |

0.10-0.50 |

0.20-0.45 |

1.00-1.50 |

≤0.015 |

≤0.003 |

≥0.20 |

<2.5 |

Mechanical Properties

|

Material |

Tensile MPA |

Elongation% |

Impact energy -20℃ |

HBW |

|

NM300 |

≥1000 |

≥14 |

≥24 |

270-300 |

|

NM360 |

≥1100 |

≥12 |

≥24 |

330-390 |

|

NM400 |

≥1200 |

≥10 |

≥24 |

370-430 |

|

NM450 |

≥1250 |

≥7 |

≥24 |

420-480 |

|

NM500 |

≥1250 |

≥7 |

≥24 |

≥470 |

|

NM550 |

≥1250 |

≥7 |

≥24 |

≥530 |

|

NM600 |

≥1250 |

≥7 |

≥24 |

≥570 |

Mn13 High Manganese Carbon Steel Plate

Chemical composition (%)

|

Material |

C |

Si |

Mn |

P |

S |

|

Mn13 |

0.90-1.20 |

0.30-0.80 |

11.0-14.0 |

≤0.035 |

≤0.30 |

Mechanical properties

|

Tensile Strength |

Yield Point |

Elongation |

Impact Resistance |

Initial Hardness (HB) |

Hardness after Hardened (HB) |

180° old Bending Test |

|

≥900MPa |

≥295 |

≥40% |

ak≥90J |

200-250 |

≥300 |

Qualified |

For the steel industry, customers care not only about quality control, on-time delivery and providing favorable prices, but also about adding value through the services we provide. We work with customers to continuously improve steel quality.

Bao Steel (Qingdao) Co., Ltd.

Bao Steel (Qingdao) Co., Ltd. is a large-scale enterprise group focusing on steel production and raw material import and export trade, integrating trade, industry, logistics and services, covering an area of 60,000 m². After years of development, the business scope has expanded to the Middle East, Latin America, Australia, South Korea, Europe, Russia and even Africa. It has established a broad product sales and raw material procurement network at home and abroad, and sincerely provides customers with professional and thoughtful services. After development, the company already has a group of high-quality employees with professional knowledge and experience in production, trade, shipping, modern logistics and other fields. We will make full use of modern management and information technology to cultivate our unique core capabilities and provide high-quality, reliable value-added services and strong support to all sectors of society.

Honor

The company has passed ISO9001 international quality management system certification and CE certification, and obtained provincial enterprise letters of credit, enterprise credit certificates, etc.

RELATED PRODUCTS

FAQ

Message